Hybrid 3D Printing of Soft Electronics

Citation:

| 2.01 MB |

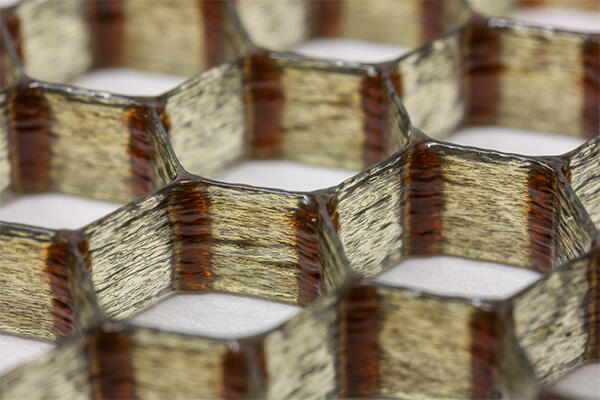

Printing multifunctional materials across multiple scales for soft sensors, electronics, and robotics.

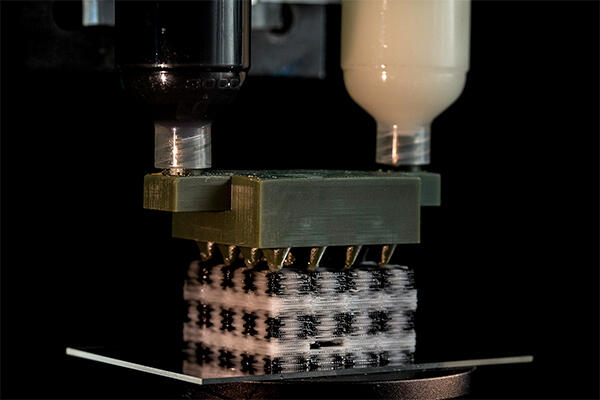

Novel materials and printhead designs are being developed to create hierarchically architected matter.

Vascularized organ-specific tissues are created through the integration of developmental biology and biomanufacturing for use in drug screening, disease modeling, and regenerative medicine.

Recent News

Creating sustainable, cell-cultured fish fillets using cardiac tissue engineering techniques

| 2.01 MB |

| 2.09 MB |

| 6.44 MB |

The Lewis Lab is seeking the next generation of graduate students and postdoctoral researchers to join our multidisciplinary team. We welcome candidates with expertise in one or more areas, including materials science and engineering, polymer chemistry, stem cell biology, biomedical engineering, mechanical engineering, and electrical engineering.