Photoswitchable Covalent Adaptive Networks Based on Thiol-Ene Elastomers

Citation:

| 5.75 MB |

Our research focuses on creating the next-generation functional, structural and living materials by leveraging our expertise in materials science, stem cell biology, fluid mechanics, 3D printing, and biomanufacturing.

Area of Research

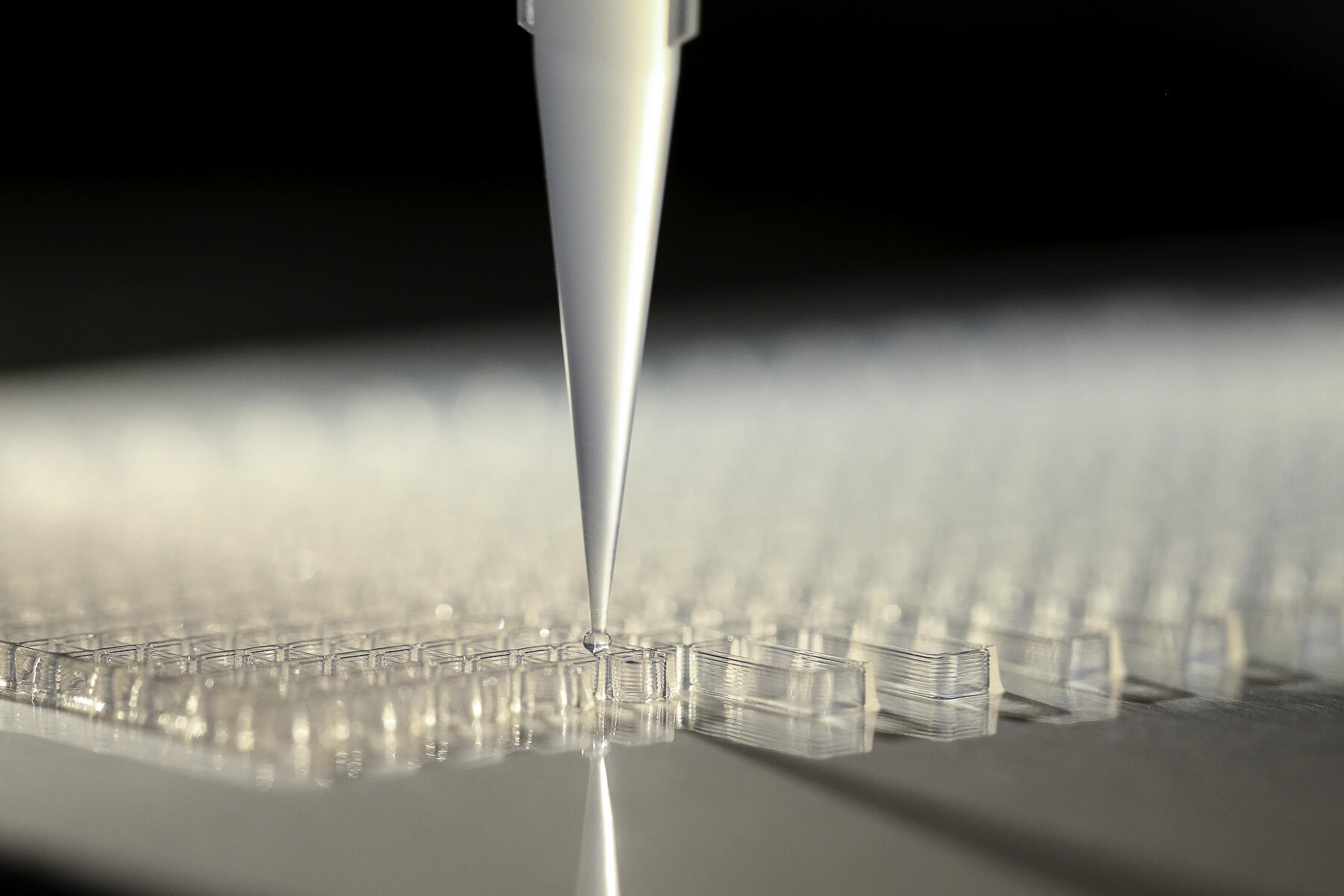

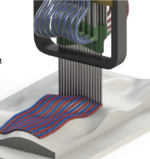

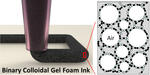

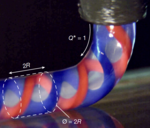

We design novel inks for 3D printing of functional materials with locally tailored composition, structure, and properties. We focus on controlling their composition and structure at the molecular and nanoscale via chemical synthesis and at the microscale and macroscale via 3D printing. Our viscoelastic inks can be produced from a broad array of building blocks, including metallic and oxide particles, polymers, hydrogels, and functional elastomers, which are suitable for our direct ink writing (DIW) and embedded 3D (EMB3D) printing methods. To further control architecture across multiple scales, we have developed custom printheads, e.g., switching, mixing, core-shell, and multinozzle arrays. Our additive manufacturing platform enable the creation of myriad devices with programmed functionality, including printed electronics, rechargeable batteries, sensors, actuators, and soft robots.

| 5.75 MB |

| 2.07 MB |

| 1.86 MB |

Area of Research

We are employing novel printing methods and custom printhead designs to create hierarchical architectures with locally tailored composition, structure, and properties. Specific materials and architectures of interest range from stimuli responsive, shape-morphing hydrogels to epoxy-based composites. The architecture and composition of the printed structures can also be tuned by using custom-designed printheads with specialized features including multi-material, multi-nozzle, rotational, and adaptive capabilities.

| 0 bytes |

| 3.11 MB |

| 2 MB |

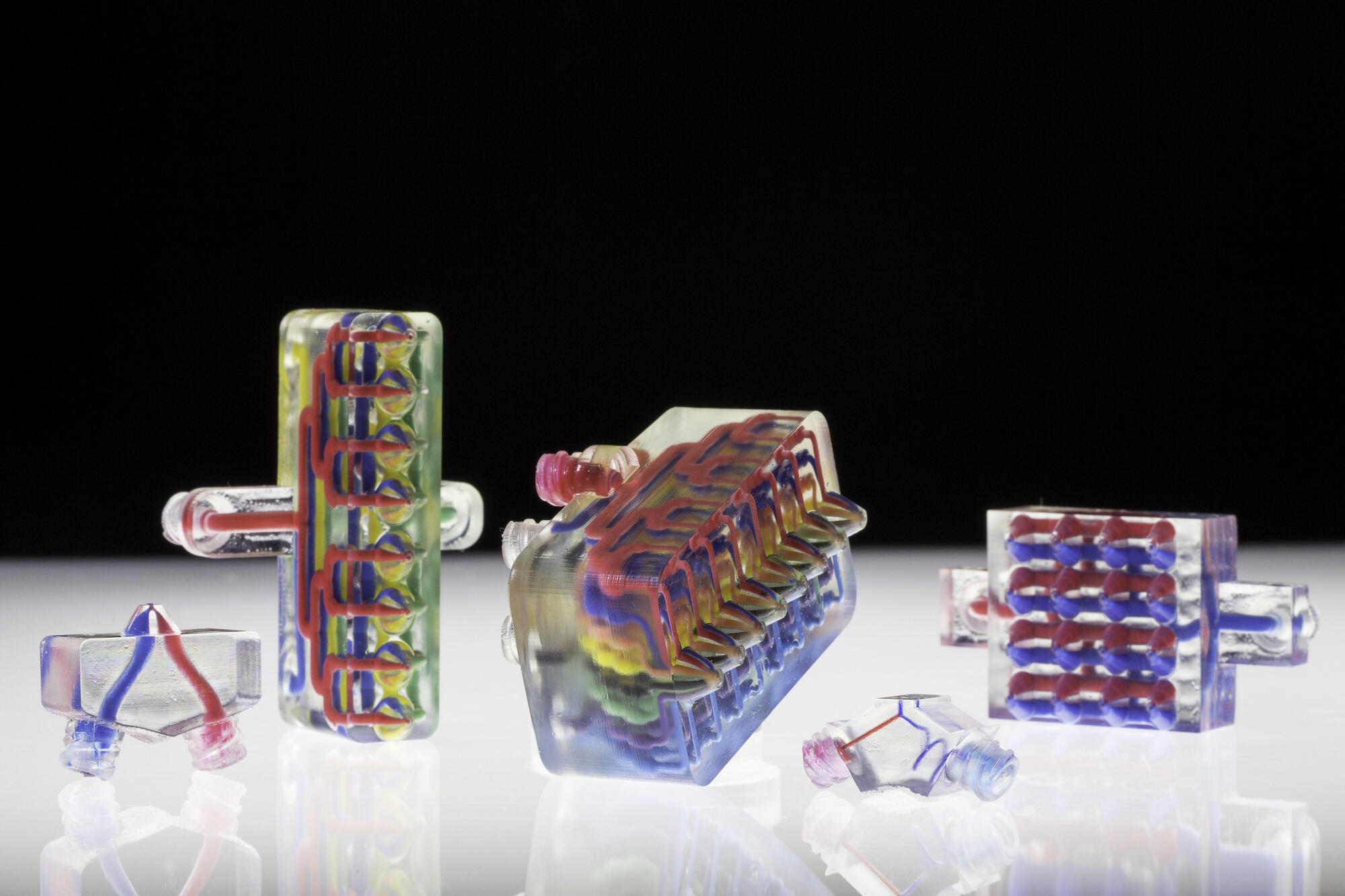

Area of Research

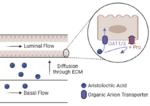

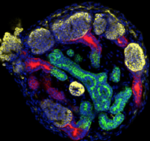

We are designing new bioinks and innovative multi-material 3D bioprinting methods to create vascularized human tissues for drug testing, disease modeling, and therapeutic use. We combine stem cell biology, organoid differentiation, bioprinting methods, and customized bioreactor designs to recapitulate the complex multicellular composition, organization, and function of organ-specific human tissues, including cardiac, kidney, adipose, and cerebral tissues. By directly embedding perfusable channels (vessels) within densely cellular tissues, we can create functional human tissues at organ scale. We are collaborating with leading biology, genetic engineering, and clinical experts in the Boston area as well as pharmaceutical companies around the world.

| 2.19 MB |

| 7.83 MB |

| 4.09 MB |

| 2.57 MB |

| 4.74 MB |

| 12.66 MB |

| 0 bytes |

| 2.77 MB |

| 0 bytes |

| 4.09 MB |

| 4.34 MB |

| 0 bytes |

Recent protocols in developmental biology are unlocking the potential for stem cells to undergo differentiation and self-assembly to form “mini-organs”, known as organoids.

Ideas have been communicated for millennia by printing images and words onto surfaces. Now, it is possible to transform ideas directly into three-dimensional objects using printing methods.

20 people die waiting for an organ transplant every day in the US, but lab-grown organs so far lack the cellular density and functions required to make them viable replacements.

3D printing enables one to rapidly design and fabricate materials in arbitrary shapes on demand.

Developed by Harvard researchers, the first autonomous, untethered, entirely soft robot — nicknamed the octobot — could revolutionize how humans interact with machines.

In this video, see the laser-assisted method developed by Wyss Core Faculty member Jennifer Lewis that allows metal to be 3D printed in midair.